Blanketing

EQUIPMENT AND PIPING BLANKETING USING STEAM FROM A FLAME TUBE BOILERS

This process injects steam into vessels and process piping to purge them of hydrocarbon vapours. This is a necessary preliminary on process equipment and piping prior to inspection and/or maintenance.

The injection of steam for blanketing simultaneously provides an internal cleaning by removing residual oil that has accumulated on internal surfaces. These residuals together with condensate are pumped to a wastewater treatment plant – a mobile unit also furnished by TSL.

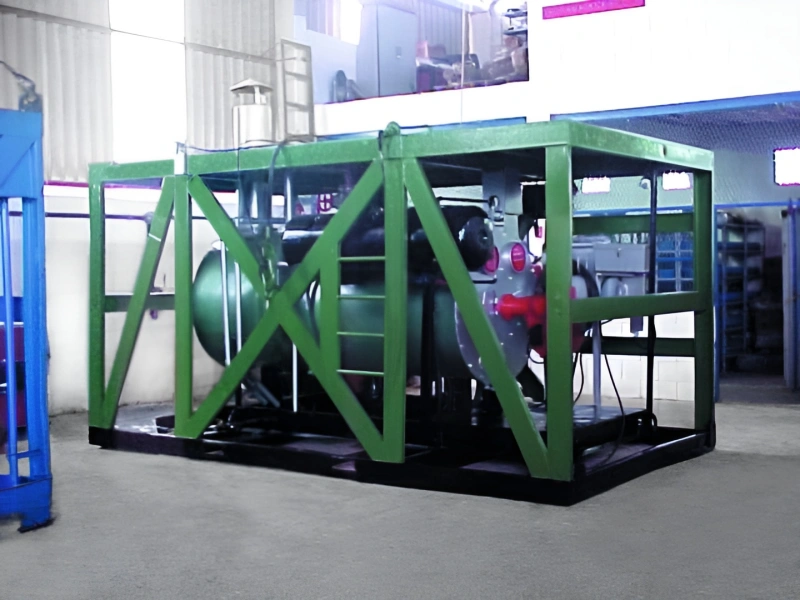

The flame tube steam generators normally used for this service provide steam at 300psi and are available with various flow rates - from 650 to 10000 kg/hr. Operational procedures and operator qualifications follow the requirements of NR-13 (ABNT standard for steam boilers).

Other uses for our steam generators include fluid heating or via heat exchangers or direct heating as required by the client’s process.

Applications

- Off-shore production and drilling rigs

- Petroleum terminals

- On-shore petroleum facilities

Advantages

- Compact self-contained equipment that is prepared for off-shore operation with complete safety

- Highly skilled operatives

- Preventive maintenance of our stem generators ensures that it is “as new” for each new job.